Impact

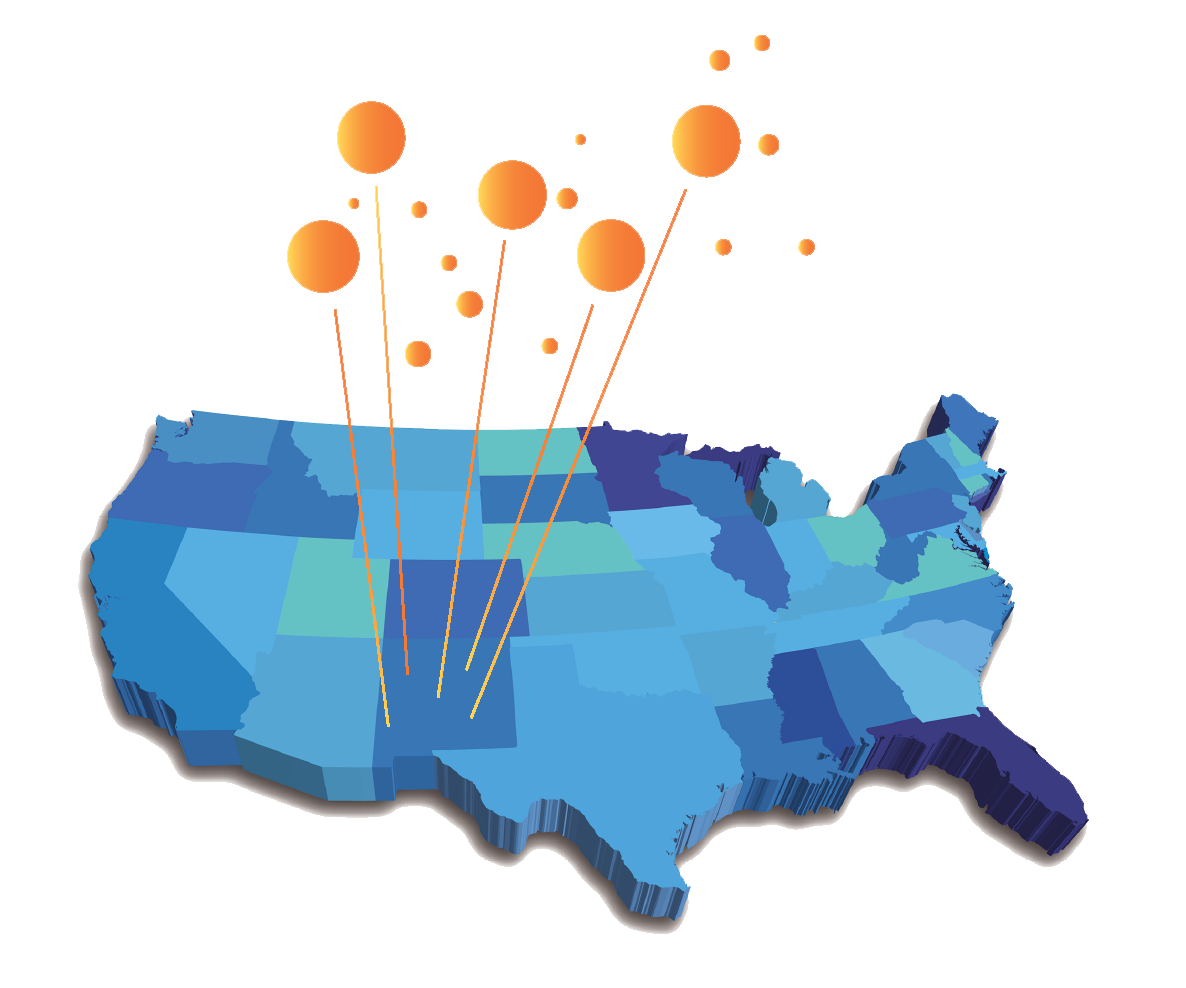

Available to all manufacturers throughout the state, New Mexico M.E.P. works annually with over 110 manufacturers in New Mexico. Take a look! Shown here are a group of featured milestone stories of some of the work performed across the state, and impacts made to our state's economy.

Hover over each dot on the map to read about some of New Mexico M.E.P.'s impacts.

Deming

Compass Components/Value stream mapping event with key personnel evaluated current production process for transmission harness products and incorporat...

Farmington

Valley Mills/$2m cost savings due to location designation, opened new markets and customers, $40,000 annual revenue increase due to new products. Work...

Albuquerque

IDSNM/Sales increase from $580,000 in 2019 to $1.1 million in 2020, moved from 1,200 sf facility to 6,000 sf. When Integrated Deposition Solutions (ID...

New Mexico M.E.P. milestone stories across New Mexico

Companies we work with span from cosmetics to food manufacturing to high-tech, electronic, industrial, plastics, and digitization. Whether you have 1 employee or 400, we're here to help!

Want to see us in your county?-Clay Allison, CEO, Wicked Edge/Hollowpoint of Santa Fe"New Mexico M.E.P. broke through all the personality types and odd workarounds at my company and streamlined the entire process so that we went from a stagnant company to one with increased revenue."